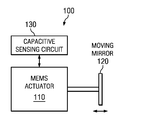

Self calibration for mirror positioning in optical MEMS interferometers

Description

Micro Electro-Mechanical Systems (MEMS) refers to the integration of mechanical elements, sensors, actuators and electronics on a common silicon substrate through microfabrication technology. A Micro-Electro-Mechanical System (MEMS) apparatus provides for self-calibration of mirror positioning of a moveable mirror of an interferometer. At least one mirror in the MEMS apparatus includes a non-planar surface. The moveable mirror is coupled to a MEMS actuator having a variable capacitance. The MEMS apparatus includes a capacitive sensing circuit for determining the capacitance of the MEMS actuator at multiple reference positions of the moveable mirror corresponding to a center burst and one or more secondary bursts of an interferogram produced by the interferometer based on the non-planar surface. A calibration module uses the actuator capacitances at the reference positions to compensate for any drift in the capacitive sensing circuit.

Aspects

A MEMS interferometer configured to produce an interferogram, the MEMS interferometer comprising: at least one mirror optically coupled to receive and reflect light, a first mirror of the at least one mirror having a non-planar surface, the non-planar surface comprising a main surface and at least one additional surface offset from the main surface; and a MEMS actuator coupled to a moveable mirror of the at least one mirror to produce a displacement thereof, the MEMS actuator having a variable capacitance; a memory maintaining a table mapping stored capacitances of the MEMS actuator to respective stored positions of the moveable mirror; a capacitive sensing circuit coupled to the MEMS actuator, the capacitive sensing circuit configured to: sense a first measured capacitance of the MEMS actuator at a first reference position of the moveable mirror corresponding to a center burst of the interferogram; and sense a second measured capacitance of the MEMS actuator at a second reference position of the moveable mirror corresponding to a secondary burst of the interferogram produced as a result of the non-planar surface; and a calibration module configured to use the first measured capacitance at the first reference position and the second measured capacitance at the second reference position to determine a correction amount to be applied to the stored capacitances in the table.

Patenting Status

Patent Granted

Status

Patented

Submit Your Intellectual Property Send Your Feedback

EgyptInnovate site is not responsible for the content of the comments