Single insertion trimming of highly accurate reference oscillators

Description

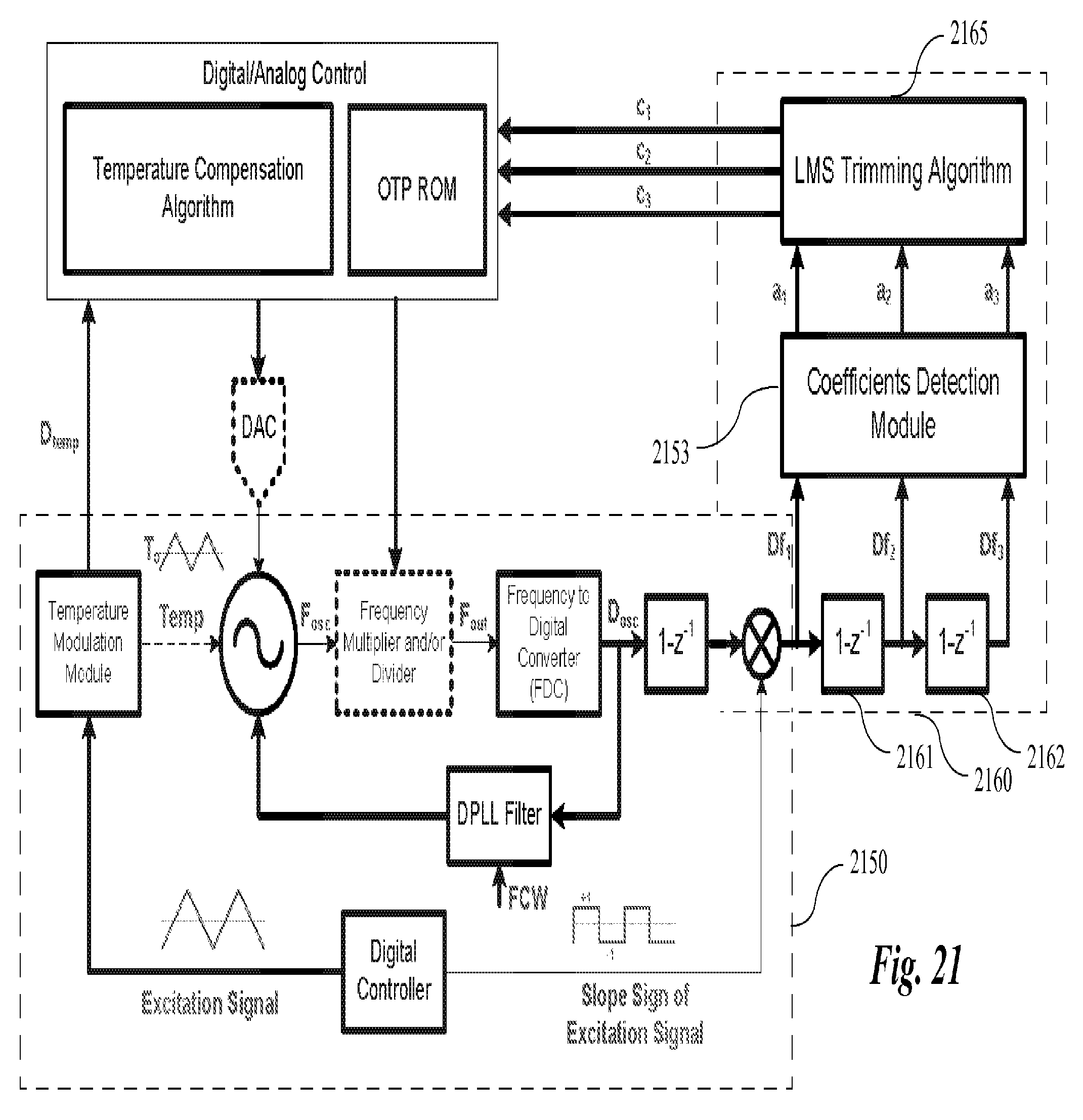

A highly integrated monolithic self-compensated oscillator (SCO) with high frequency stability versus temperature variations is described, together with a cost effective single insertion point trimming (SPT) algorithm. The SPT is utilized to adjust the phase and frequency of the SCO to meet frequency stability versus temperature and frequency accuracy requirements for a reference clock. The techniques used in the SPT algorithm provide a robust, fast and low testing cost for the SCO. Moreover, the concepts and techniques utilized in the SCO SPT can be used effectively for any temperature compensated oscillator (TCO) including TCXO, MEMS, FBAR and RC oscillators. Additionally, the described SPT algorithm is capable of measuring the temperature sensitivity of any oscillator, estimating suitable temperature compensation parameters and adjusting the oscillator frequency to the required value simultaneously.

Aspects

The ever increasing complexity of electronic systems due to requirements of supporting multiple standards, increased functionality, higher data rates and memory in a smaller size and at a lower cost is pushing designers to increase the integration level through the development of Systems on Chip (SoC) in deep submicron Complimentary MOS (CMOS) technologies to benefit from the increased gate density. Every application requires a reference clock where the oscillator frequency must not vary due to changes in supply voltage and temperature by more than a specific amount. Quartz crystal oscillators (XOs) are the industry standard for generating a reference clock. The mature and stable technology of quartz crystals permits excellent control on the manufacturing process to select an exact cut angle to produce superior performance. Crystal oscillators stemming from the very high quality factor (Q) of the quartz crystal can achieve high frequency accuracy, low frequency drift with temperature and low phase noise. Consequently, crystal oscillators dominated the commercial market for many decades. However, crystals have not managed to scale nor integrate thus limiting the size and cost reduction of the reference clock. Recent efforts in using high-Q Micro-Electro-Mechanical Systems (MEMS) resonators and Film Bulk Acoustic Resonators (FBARs) have illustrated possibilities of integrating a high-Q element and Application Specific Integrated Circuits (ASIC) in the same package. The cost of a MEMS resonator is lower than a quartz one owing to the very high number of resonators on a single MEMS wafer. Expensive ceramic packaging of crystal oscillators is also reduced to low cost plastic packaging. However, the assembly cost of a MEMS-based solution requires stacking of the wafer level packaged MEMS die and the CMOS die. Additionally, elaborate production testing is required to trim each part to the required performance over the specified temperature range. This process may require more than one temperature insertion to estimate the temperature compensation parameters and to adjust the oscillator frequency to the required value. This makes the testing cost of MEMS and FBAR oscillators too high to compete with XOs for consumer applications.

Patenting Status

Patent Granted

Status

Patented

Submit Your Intellectual Property Send Your Feedback

EgyptInnovate site is not responsible for the content of the comments